ISO-Chemie’s thermal insulating and load bearing bracket support system has been specified to provide energy efficiency improvements to an Edwardian property in Oxfordshire. The move sees WINFRAMER units retrofitted as part of an initiative to bring the poorly insulated solid walled house built in 1909 in Oxford, up to current energy efficiency standards, providing better quality accommodation for the homeowner along with long-term cost savings.

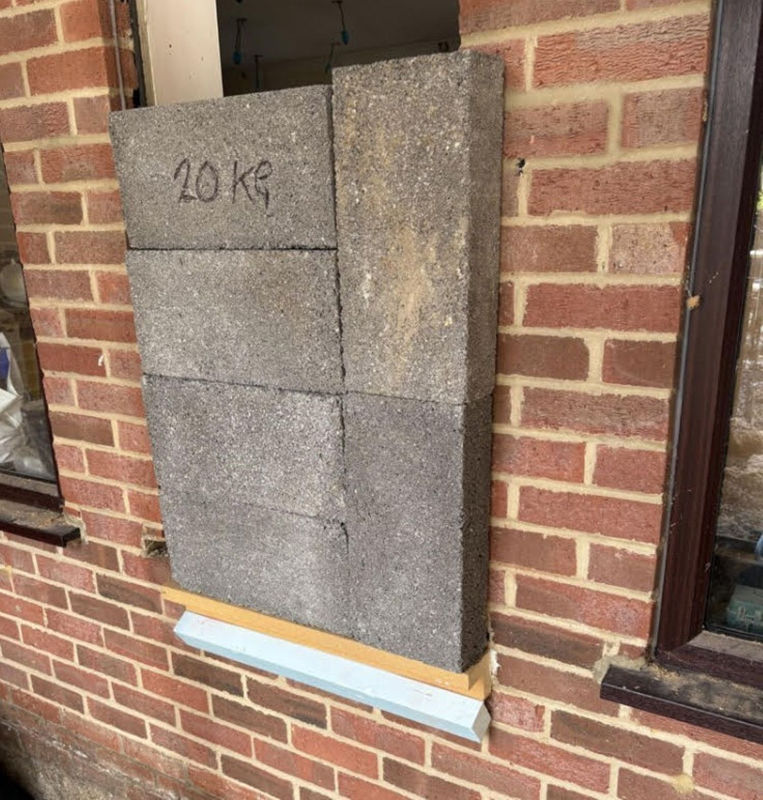

Passivhaus certified and fire rated to up to 30 minutes, WINFRAMER is a prefabricated installation frame, manufactured to accommodate cavities up to 250mm that allows windows to be supported independently from the face of the wall regardless of any external cladding being in place.

Quick and easy to install, the product’s application in Oxford is seen as part of a solution to meet a wider Government strategy to reduce carbon levels in housing that has single skin walls or non-cavity walls - these buildings have a reputation for leaking considerable amounts of energy, heat and sound.

Nikki Lambert of development contractor Lambert Home Builds, said the project was a whole house retrofit and added: “Using the WINFRAMER system is a game changer for us as the existing windows are being replaced with new high performance triple glazing. They are then moved into the external wall insulation system, where it’s integral to have a secure fixing system as well as a means to mitigate thermal bridging.”

Andy Swift, ISO-Chemie’s sales and operations manager – UK and ROI, added: “Using WINFRAMER as a platform for the windows to be moved forward, allows a cavity wall to be created outside the existing one. This can then be filled with insulation to massively improve thermal efficiency. As it’s thermally efficient and airtight, WINFRAMER is proving to be an easy and cost-effective way to improve the quality of properties.”

The composite WINFRAMER brackets can bear heavy window loads, including bi-fold doors, to provide a reliable, strong and high-performance support frame. Installation is quick with windows attached directly and secured mechanically using either standard fixing screws or fixing lugs in the usual manner.

A hinged insulation core combines with the composite structural bracket to become an integral part of the overall wall structure, providing compliance with Building Energy Act requirements and the RAL quality assurance association.

ISO-Chemie is one of Europe’s main producers of impregnated foam sealants, specialising in the manufacture of foam products from polyethylene (EPE), polypropylene (EPP) and polyurethane (PUR) using the latest production techniques.